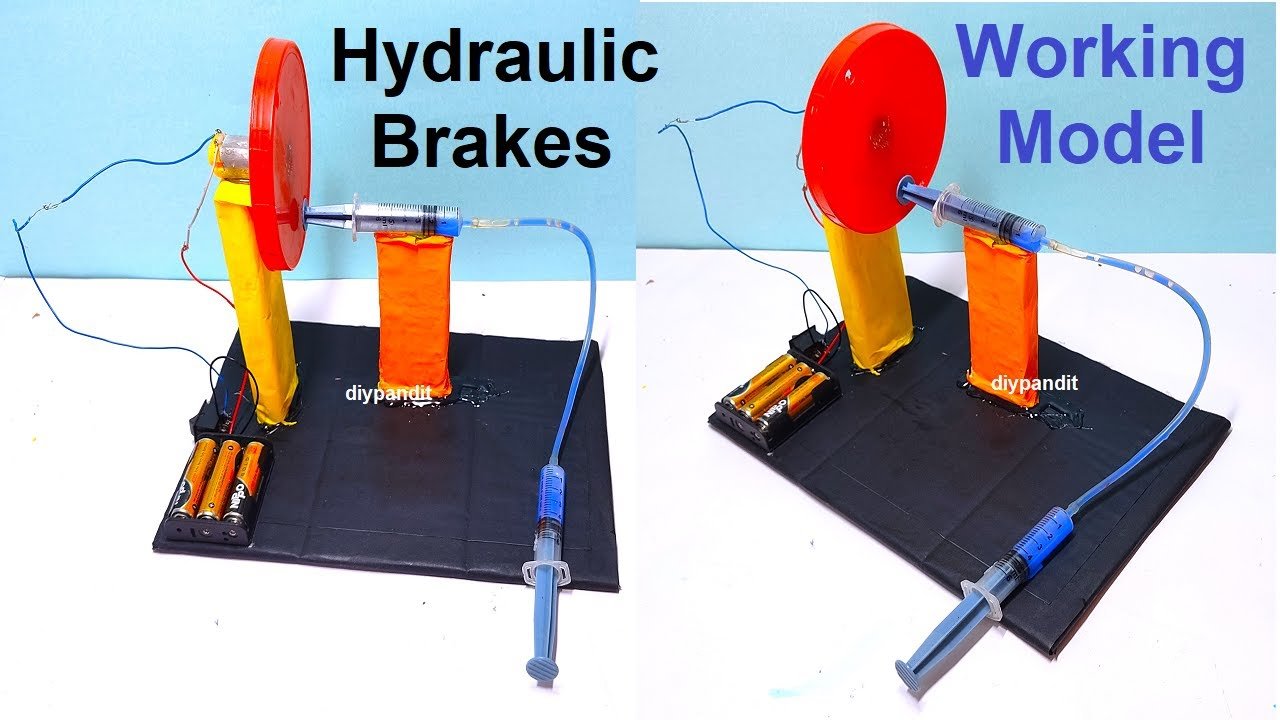

The hydraulic brake working model with a wheel, DC motor, and syringes provides a practical and visual representation of the principles behind hydraulic braking systems in vehicles.

This hands-on project enhances understanding of hydraulic pressure transmission and its application in vehicle safety systems.

Creating a hydraulic brake working model with a wheel, DC motor, and syringes involves simulating the principles of a hydraulic braking system with a rotating wheel.

Below is an explanation of how to construct and understand this model:

Materials Needed:

- DC motor with a small wheel or pulley

- Two syringes

- Plastic tubing

- Wooden base or sturdy surface

- Cardboard or foam board

- Wooden blocks or small cylinders

- Hot glue gun and glue sticks

- Small plastic containers (optional)

- Brake fluid or water

- Scissors

- Marker

Construction Steps:

- Base Construction:

- Prepare a stable base using a wooden board or any sturdy surface.

- DC Motor Mounting:

- Attach a DC motor to the base. Make sure the wheel or pulley is aligned to rotate freely.

- Syringe Mounting:

- Attach two syringes to the base using hot glue, placing them on either side of the rotating wheel.

- Plastic Tubing Connection:

- Connect plastic tubing to the nozzles of the syringes. Ensure a tight and secure connection using hot glue.

- Brake Caliper Representation:

- Cut small cardboard or foam board pieces to represent brake calipers. Attach these pieces to the end of the plastic tubing connected to the syringes.

- Piston Representation:

- Attach wooden blocks or small cylinders to the other ends of the plastic tubing to represent pistons in the brake calipers.

- Fluid Reservoirs (Optional):

- If using brake fluid, place small plastic containers near the syringes to serve as fluid reservoirs. Connect them to the plastic tubing.

- Labeling:

- Label the syringes as “Master Cylinder” and “Slave Cylinder” using a marker.

How It Works:

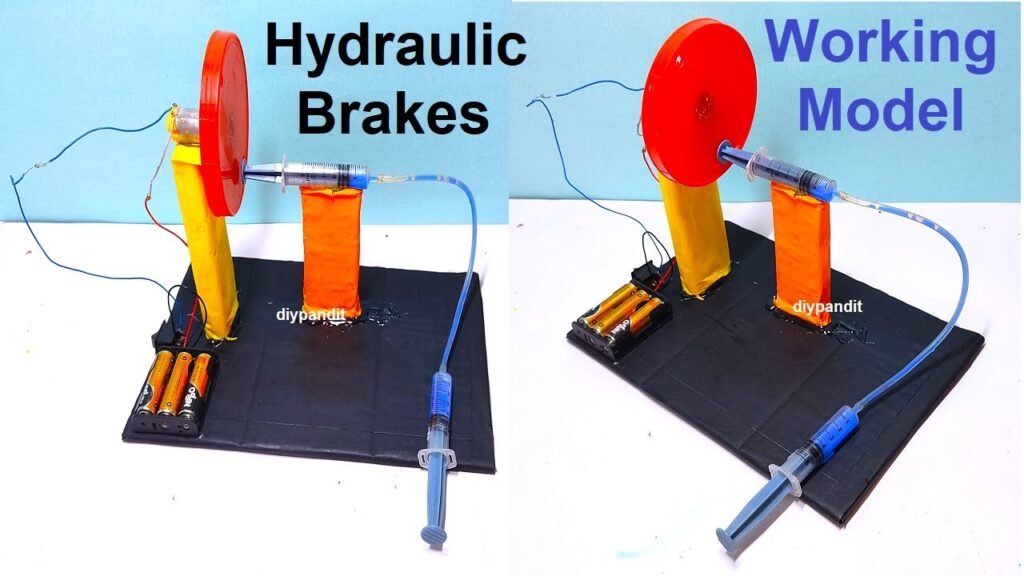

- DC Motor Rotation:

- When the DC motor is powered and the wheel rotates, it simulates the motion of a vehicle wheel.

- Master Cylinder (Syringe 1):

- As the wheel rotates, push the plunger of the master cylinder (syringe 1) in. This creates hydraulic pressure in the plastic tubing.

- Slave Cylinder (Syringe 2):

- The hydraulic pressure is transmitted to the slave cylinder (syringe 2), causing its plunger to move out. This simulates the action of brake fluid forcing a piston in the brake caliper to engage.

- Brake Caliper Action:

- As the pistons in the brake caliper move, they represent the squeezing action on the wheel, simulating the braking process.

- Release and Reset:

- When the master cylinder plunger is released, the hydraulic pressure decreases, allowing the brake caliper to reset to its initial position.