This model represents the paper output system of a printer. Real printers use motors to push printed paper out. Here, we’re using a simple hydraulic mechanism.

When we press this syringe, the connected syringe inside pushes the printed paper forward. It’s a basic example of how hydraulics can be used in machines to move things without electricity.

Video Steps to Make the Model:

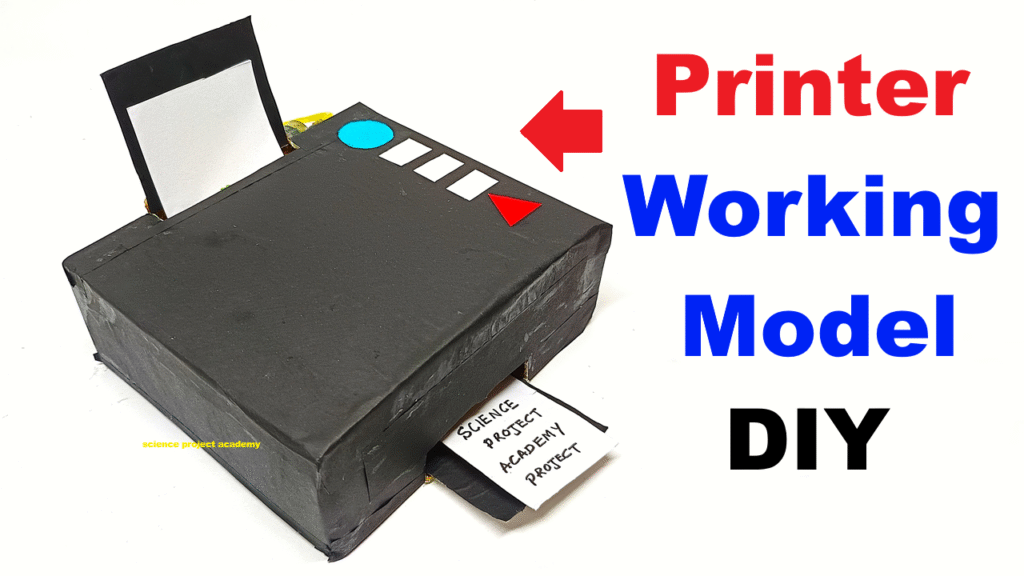

Step 1: Make the Printer Box

- Take a cardboard box (approx. 25 cm x 15 cm x 10 cm).

- Cut a slot on the front side — this will be the paper output tray.

- Make a top loading slot to insert paper (optional).

- Decorate it with color paper to mimic a real printer (use black, grey, or multicolor theme).

Step 2: Prepare the Syringe Mechanism

- Fix one syringe (A) inside the printer box at the rear end with its plunger facing forward.

- Attach a pipe to the nozzle of syringe A, and connect it to a second syringe (B) which remains outside the box as the control.

- Attach the plunger of syringe A to a horizontal push board made from cardboard or a stiff paper sheet.

- Stick 2–3 printed paper slips (A5 or A6) in front of the push board.

Step 3: Output Pusher System

- When you press the external syringe B, pressure transfers to syringe A.

- The plunger of syringe A pushes the push board, which in turn moves the printed slips out through the front slot.

- It looks like the printer is pushing printed content!

Step 4: Decoration

- Paste buttons, icons like WiFi, ON/OFF, and a paper indicator (just for realism).

- Add a small display window using black paper (to show “Printing…” or “Ready”).

How It Works:

Pressing the external syringe sends water pressure through the pipe to the internal syringe, whose plunger pushes forward a stack of printed slips, imitating how real printers eject paper after printing.

Scientific Principle Used:

- Pascal’s Law in Hydraulics: Pressure applied to one part of a fluid is transmitted equally in all directions.

- Demonstrates how force can be transferred using liquid pressure to perform work (like pushing paper).