Tired of watching your water bill skyrocket while your urban garden thirsts for more?

Imagine a garden that practically waters itself, saving you money and the planet. This video reveals a simple DIY system that recycles household water, making your urban garden thrive without the constant tap of high costs.

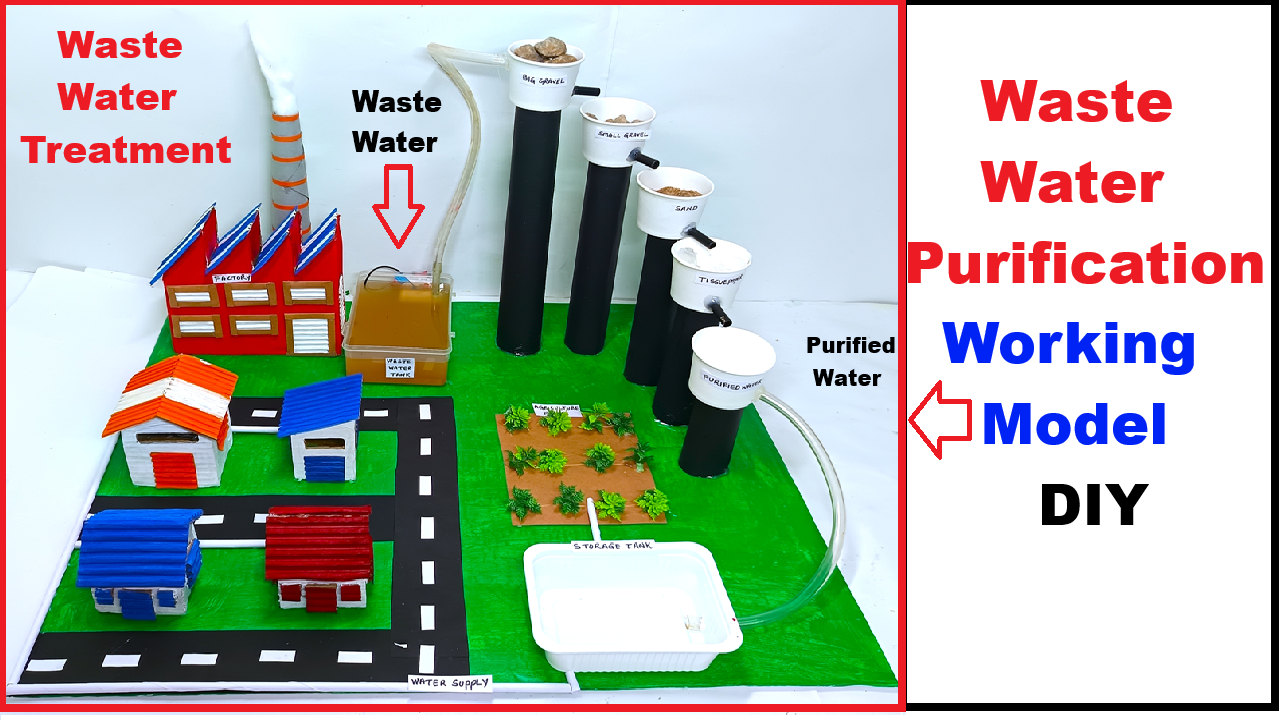

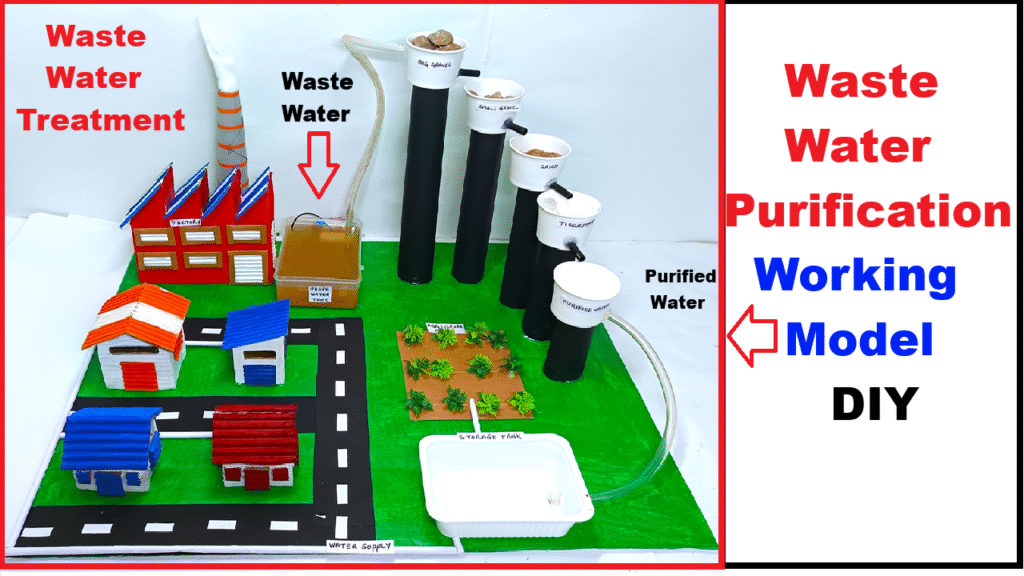

This model shows how wastewater from a factory can be collected, treated, and purified through multiple stages — just like in real treatment plants — using sedimentation, filtration, and disinfection processes powered by a small motor pump.

Materials Required:

Base Setup:

- Cardboard / Thermocol board (for mounting everything)

- Mini water pump (DC 3V–12V motor pump or aquarium pump)

- Plastic pipe/tube (to connect water flow between cups)

- Small factory model (made from cardboard or paper box, with cotton smoke for realism)

- 4–6 paper cups or plastic glasses (for each treatment stage)

- Dirty water (mix of mud, detergent, small pieces of paper, and oil)

Purification Materials:

- Gravel (large pebbles)

- Sand (medium and fine layers)

- Activated charcoal (for removing color and odor)

- Cotton or filter paper (for fine filtration)

- Chlorine tablet or a drop of diluted bleach (optional, for disinfection demo)

Decoration:

- Paint, markers, labels for each stage

- Chart paper, glue gun, scissors, tape

- Small LED light (optional for “factory effect”)

Step-by-Step Construction:

Step 1: Prepare the Base

- Take a large cardboard base.

- Mark out the layout — place the factory model on one corner and line up 5–6 paper cups next to it to represent treatment stages.

- Label each stage: Screening → Sedimentation → Filtration → Disinfection → Clean Water.

Step 2: Create the Factory Model

- Make a small rectangular “factory building” from cardboard.

- Add a small chimney using a rolled paper tube with cotton on top (for smoke).

- Cut a hole at the bottom of the factory to attach a pipe — this will act as the wastewater outlet.

- Connect the outlet pipe from the factory to the first paper cup (Screening Chamber).

Step 3: Setup the Paper Cups (Treatment Stages)

- Line up 5 paper cups on the base slightly inclined, so water flows from one to the next through small connecting pipes.

- Connect each cup with small straws or flexible tubing near the top rim to allow overflow to the next stage.

Step 4: Stage 1 – Screening

- Place a small piece of wire mesh or plastic net inside the first cup.

- This removes large particles like leaves, paper, or debris when water passes through.

- Label it “Screening Chamber.”

Step 5: Stage 2 – Sedimentation Tank

- In the second cup, pour the dirty water from Stage 1.

- Allow it to settle so heavier particles sink to the bottom.

- You can add a divider (half-cut cardboard) to make it look like a tank.

- Label it “Sedimentation Tank.”

Step 6: Stage 3 – Filtration Unit

Use 2 or 3 paper cups stacked vertically or connected with tubes to form a multi-layer filter:

Cup 1 (Bottom):

- Fine gravel and small stones.

Cup 2 (Middle):

- Coarse sand → fine sand layer.

Cup 3 (Top):

- Activated charcoal → cotton or filter paper.

As the pump moves water upward, it will pass through each layer, getting cleaner at every stage.

Label this section as “Filtration Unit.”

Step 7: Stage 4 – Disinfection Unit

- The filtered water flows into another cup (Disinfection Stage).

- Add one drop of diluted chlorine solution (for display only — don’t drink).

- Or use a small UV LED light to demonstrate modern purification.

- Label this “Disinfection Chamber.”

Step 8: Stage 5 – Clean Water Collection

- The last cup collects the purified water.

- Label it “Clean Water Outlet.”

- Show the difference by placing this clean cup beside the dirty water sample from the start.

Step 9: Water Circulation Using Pump

- Connect the mini water pump at the last stage to recirculate the clean water back to the factory inlet (creating a full water loop).

- Use transparent tubing for visual clarity.

- Power the pump with a 9V battery or USB adapter for safe demonstration.

- When switched on, the dirty water from the factory flows through each stage and returns clean — creating a working model with continuous flow!