A hydraulic press is a machine that uses liquid pressure to compress or shape materials. It works on the principle of Pascal’s law, which states that pressure applied to a liquid is transmitted equally in all directions.

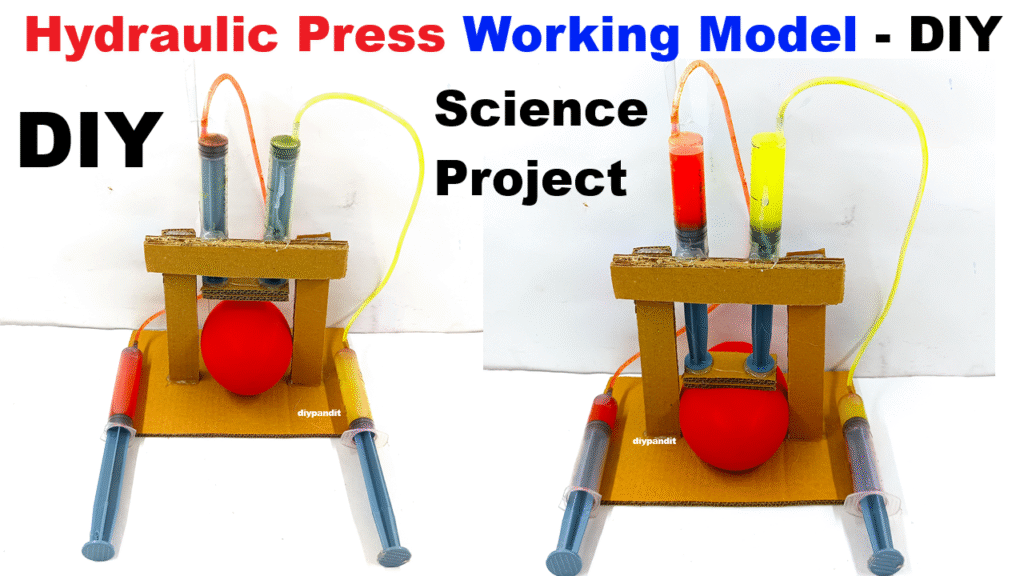

This model uses hydraulic pressure to compress a balloon or soft object between two platforms, showing how force applied to a small area can be transferred and multiplied using liquid-filled syringes.

This is a Hydraulic Press model. It works on Pascal’s Law, which states that pressure applied to a fluid is transmitted equally in all directions. When I push one syringe, water transfers the force to the other syringe, lifting the upper platform and pressing the object. This simulates how real hydraulic presses work in machines and factories.

Materials Required:

- 2 large syringes (20 ml or 50 ml)

- Flexible plastic tube (to connect the syringes, fits tightly on nozzle)

- Cardboard (for press platform and frame)

- Glue gun or Fevicol

- Tape and scissors

- Water (to fill the system)

- Balloon or sponge (to act as the object being pressed)

- Optional: Food coloring for colored water

Video Step-by-Step Instructions:

1. Prepare the Hydraulic System:

- Fill both syringes with water (remove all air bubbles).

- Connect them using a tight plastic tube.

- Make sure water moves from one syringe to the other smoothly when you push.

2. Build the Press Structure:

- Cut and assemble 2 vertical cardboard walls with space between them to hold the balloon.

- Place a cardboard platform inside the frame (this will be your lower press base).

- Create a moving upper press platform that slides down when the second syringe lifts it.

3. Attach Syringes:

- Fix one syringe (the input syringe) on the outside, where you apply the force.

- Fix the other syringe (the output syringe) vertically under the moving platform, so its plunger pushes it up like a press.

4. Test the Pressing Action:

- Place a balloon or sponge on the lower platform.

- Push the plunger of the input syringe — the water pressure will lift the plunger of the output syringe and press the balloon.